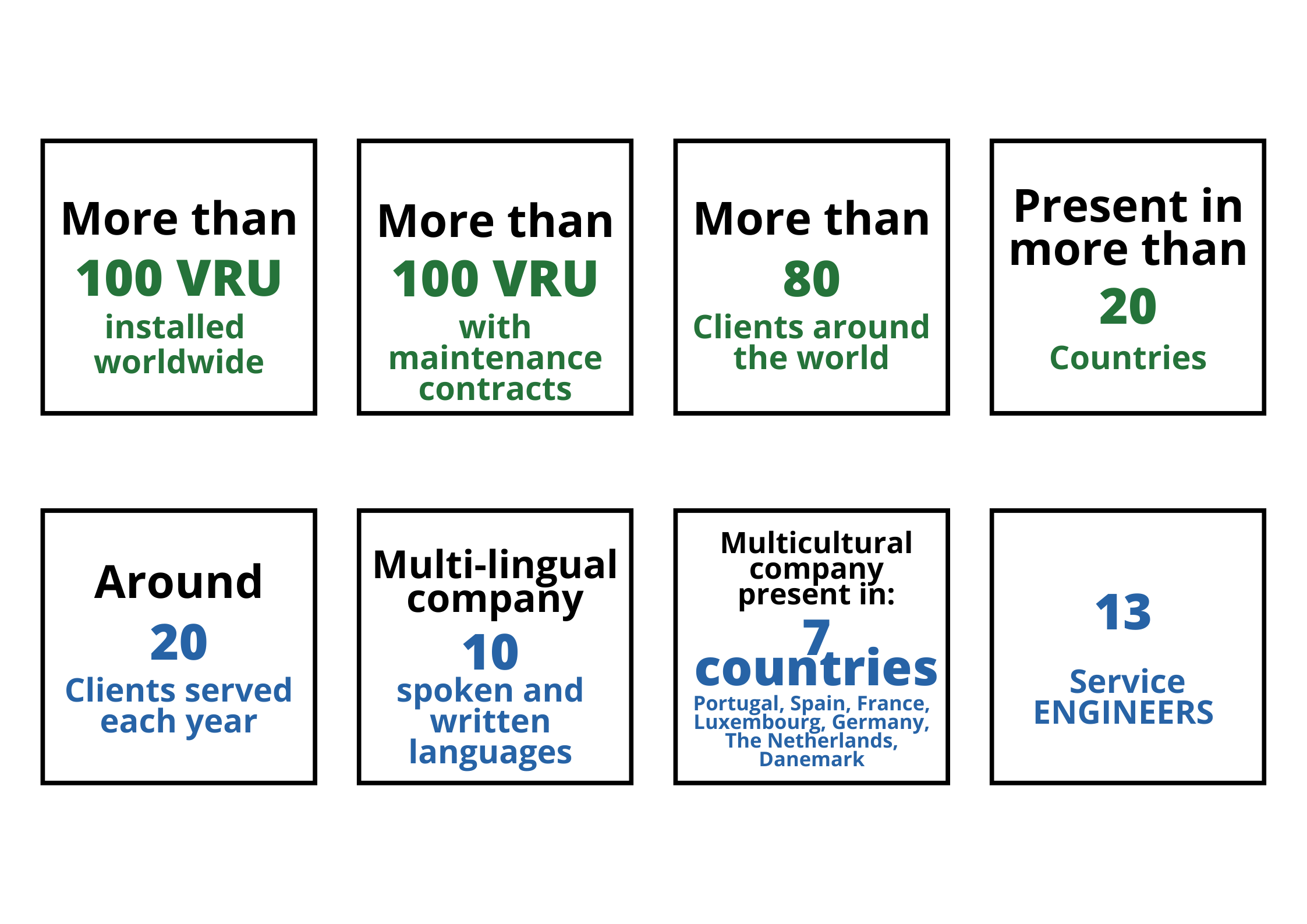

LUVEBA is the European leader in VRU maintenance and improvement, for all of the manufactured brands, for the recovery of Volatile Organic Compounds (VOCs), operating in environments with hazardous atmospheres.

Client benefits

LUVEBA solutions allow to guarantee to their clients VOC emissions compliant with local regulation, and a constant availability of your VRU equipment (> 99%)

The widest range of services on the market for continuous improvement of VRU performance and therefore VOC emission reduction

Experienced and qualified process engineers, expertise in multi-technology (dry vacuum pump, vane pump, liquid-ring pump, liquid-ring pump with booster, membranes)

The guarantee of a high quality of service and competences, as well as a great flexibility in an environment with the strictest safety rules

Quick intervention, client proximity and tailor-made solutions guaranteeing a minimal shutdown at your equipment.

Client benefits

LUVEBA solutions allow to guarantee to their clients VOC emissions compliant with local regulation, and a constant availability of your VRU equipment (> 99%)

The widest range of services on the market for continuous improvement of VRU performance and therefore VOC emission reduction

Experienced and qualified process engineers, expertise in multi-technology (dry vacuum pump, vane pump, liquid-ring pump, liquid-ring pump with booster, membranes)

The guarantee of a high quality of service and competences, as well as a great flexibility in an environment with the strictest safety rules

Quick intervention, client proximity and tailor-made solutions guaranteeing a minimal shutdown at your equipment.

An offer fitting your needs

-

VRU Maintenance

Preventive and curative maintenance, emissions recovery solutions.

-

Projects

Turnkey, spare parts

-

Consulting & Training

Our solutions

- Maintenance

- Process engineering

- Multi-brand spare parts

- Training

Maintenance

- Preventive and curative maintenance, with a significant reduction in breakdown risk

- Works & small set-ups

- 24/7 hotline

- Remote diagnostics

- On-site FID measurements and VOC analysis

- On-site detector and analyser calibration

- Thermographic analysis

- VRU back-up in the event of a breakdown or long maintenance

- Large stock of dedicated parts available

Process engineering

- From study to comissioning

- Calculation and simulation of the VRU process

- Works and optimization of VRU processes

- Upgrade & implementation, development of automation and supervision systems (Siemens, Allen Bradley, Scheinder, Ignition, WinCC and Unity Pro…)

Multi-brand spare parts

Sales of multi-brand spare parts:

CARBOVAC, John Zink, Aker Cool Sorption, Cimarron (Jordan), Borsig…

Training

Training of local operators / partners

Our products

-

Security and reliabilityHomologation ▸ New technologies ▸ New regulations 100 % security...

-

Full coverage of existing technologiesDry screw vaccum pump ▸ Liquid ring screw pump ▸ Rotative valve screw pump ▸ Liquid ring screw pump + roots compressor...

-

Multi-environment customized solutionsTruck/train/ship loading...

LUVEBA News

-

LuvebaRevamping of a VRU built end 1990’s 08 January 2025 NewsIn 2023 Luveba was successful in proposing first step to new client, the basic engineering and design for revamping of a VRU : from LRVP + booster blower (and seal fluid circuit) technology to new vacuum pumps (oil and pallet type, R5 technology). It was then followed by second order, for ordering v...Read moreLuvebaThe Vapor Recovery Unit contains parts which need replacement. 06 November 2024 NewsOperations and maintenance may be reluctant to buy replacement parts on their own – what if model / references are now different ?It’s a job and responsibility question. Luveba can help ! Please have a look at our carousel to find out how, check our website for more information and contact us fo...Read moreLuvebaReducing the VRU Energy Consumption 02 October 2024 NewsEnergy costs are increasing so you wish to improve your consumption ? Luveba helps you. We have process, program and controls engineering knowledge and capacity to study your operations and propose energy saving improvements – starting with measuring – while maintain the NMVOC emission level...Read more

For any questions or quote request, contact us by e-mail or phone